During the latest SAFETOUCH General Assembly in Guimarães, Portugal, partners stepped back from circuitry and coatings to look at the bigger picture: how to make a device that is not only effective, but sustainable and economically sound across its entire life. Lomartov’s Sustainability Technician Ignacio Zurano Villasuso led a hands-on workshop that framed the discussion around the three pillars of sustainability — environmental, economic, and social — and how they guide SafeTouch’s product decisions. As leader of Work Package 4, Lomartov will conduct the project’s Life Cycle Assessment (LCA) and Life Cycle Costing (LCC) to capture impacts and costs from materials to end-of-life.

Why life-cycle thinking matters for SafeTouch

Life-cycle thinking, aligned with ISO 14040/14044, considers every stage of a product’s journey: raw material extraction and processing, material transport, manufacturing, distribution, use, and end-of-life. Mapping the mass and energy flows across those stages gives a holistic view of environmental hot spots and cost drivers — exactly the perspective a project needs while designs are still flexible and choices still reversible.

By examining all stages from materials to end-of-life, LCA/LCC help anticipate impacts, optimise design, and support evidence-based decisions.

LCA: a structured path from data to design choices

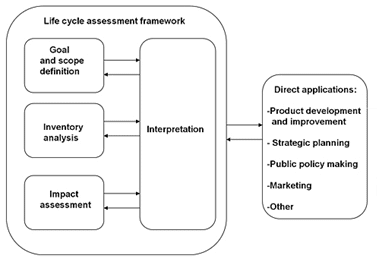

The workshop walked through the four interconnected LCA steps, each one informing the next:

- Goal & scope definition

- Life Cycle Inventory (LCI)

- Impact assessment

- Interpretation of results

Because the steps are iterative, early findings are used to refine scope, data needs, and modelling assumptions. In the short term, SafeTouch will use LCA to anticipate environmental impacts and guide design optimisation. Longer term, robust LCA results can support ecolabel or environmental certifications, substantiate sustainability claims, and help differentiate the device from competing disinfection solutions.

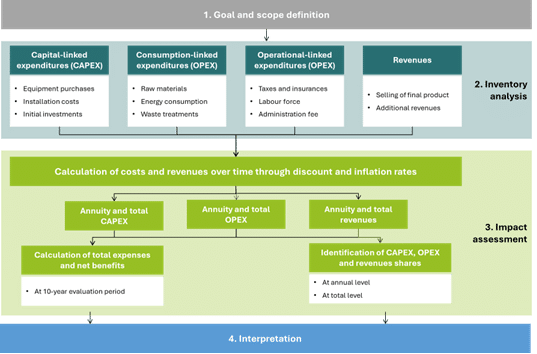

LCC: the same discipline, applied to costs and value

LCC mirrors LCA’s structure but focuses on the economics of the product across its life cycle. Using the same inventory backbone, LCC quantifies CAPEX, OPEX, and revenues, and derives decision-critical indicators including Return on Investment (RoI), Payback Period, and Net Present Value (NPV). These metrics will help the consortium evaluate financial feasibility and compare production strategies.

Making it concrete: two illustrative cases

To anchor the methods in practice, Lomartov presented two use cases close to SafeTouch’s objectives:

- LCA case – environmental footprint of hospital disinfection: This study assessed the environmental performance of hospital surface disinfection using different chemicals and cloth materials. It served as a clear example of how SAFETOUCH’s own LCA could be structured and demonstrated how environmental burdens vary depending on material choices and product design. Impacts were analysed using the Environmental Footprint 3.1 methodology.

- LCC case: insights from the Sustain-a-Print project: For the LCC demonstration, a methodological example was drawn from Lomartov’s work in the European project Sustain-a-Print. Without disclosing sensitive data, the example showed how cost inventories are developed and how economic indicators are calculated to support decision-making.

What partners took away

Although SafeTouch is still in early development, the session sparked constructive discussion on practical implementation: what data will be needed, how and when to collect it, and how LCA/LCC outcomes will feed back into device design and strategy. The immediate value is clarity — a common framework for talking about impacts and costs — and the longer-term value is better choices, earlier, with evidence to back them. In short, life-cycle thinking becomes both an analytical tool and a driver for innovation, differentiation, and long-term success.